There are thousands of building materials available in market which can be used for making various designs but following are the 5 major materials for interior and exterior building designs:

1. WPC Board

2. PVC Board

3. MDF Board

4. HDHMR Board

5. Plywood Board

So, read full blog to know in detail about these 5 major materials used for interiors and exterior building designs which consists of its industrial making, different sizes available in market, advantages & disadvantages and its application (both interior and exterior).

1. WPC Board: (Wooden Plastic Composite Board)

Wooden Plastic Composite Board is generated from a different natural wood blend such as peanut hulls, pulp, bamboo, sawdust, bark, thatch etc and mixed with plastic powder to create WPC. Wood Plastic Composite Boards has 70% of virgin polymer and 15% of wood powder, and left 15% additive-chemical. They all are mixed together to prepare a rich consistency material which can be given different shapes and sizes and cut into various dimensions. Several different colors and additive can be added to create materials with better specifications. These boards can be used as high strength coatings for furniture and interiors. WPC is utilized for decks, landscaping, floors, windows, fences, doors, rails, internal or external wall cladding.

Picture credits: McCoy Mart

WPC board available in following sizes

1220 mm X 2240 mm (4 ft X 8 ft), available in following thickness:

- 5 mm (0.20 inch)

- 6 mm (0.24 inch)

- 7.5 mm (0.30 inch)

- 11 mm (0.43 inch)

- 12 mm (0.47 inch)

- 17 mm (0.67 inch)

- 18 mm (0.71 inch)

Picture Credits: Civiconcepts

Advantage and Disadvantages of WPC Board:

Advantages:

- WPC boards are highly durable because they are 100% termite proof and waterproof.

- WPC do not corrode, rot, decay and also free of termites and fungi.

- These boards does not need extra oiling, staining and painting also it is maintenance free material.

- They are quite flexible and can be easily molded into desired shape and size.

- It is self extinguishing material and does not ignite the fire when comes in contact with fire source. Also WPC is a fire retardant and does not allow fire to get circulated.

- They are environment friendly because no trees are cut in the making of WPC board and also they are 100% VOC free. This material is made up of eco friendly building materials.

- WPC can be utilized in sunlight and does not get spoiled due to harsh sun rays but weather coat paint and polish can be done for little maintenance.

Disadvantages:

- The cost is high as compared to the products of same category.

- WPC lacks the natural wooden texture due to the absence of wood natural wood is not there.

- It is heavy in comparison to the other wooden materials.

- They comprised plastic waste and waste wooden materials, so shortcoming of the both elements can exits in this.

Application of WPC Board:

This material can be used for interiors as well as the exterior purposes.

Interiors:

It is used for making modular kitchen design, office furniture, paneling of wall, ceiling remedy, wardrobes, industrial compartment, control cabinets and panels, bathroom cabinets, window, and doors frame, and railing.

Exteriors:

In exterior applications, WPC boards can be utilized in constructions/ shuttering boards, exterior wall cladding, garden furniture, park benches and fencing, prefabrication house, different exterior applications, outdoor deck flooring.

Picture Credits: GharPedia

2. PVC Board: (Poly Vinyl Chloride Board)

PVC boards are also known as PVC foam boards otherwise known as Chevron board or Andy board. These boards are quite popular and widely used for indoor and outdoor designing. It comprises of chemical composition, PVC boards are made up of Poly Vinyl Chloride.

Picture Credits: Polytech

PVC Board are available in following sizes:

1220 mm X 2240 mm (4 ft X 8 ft), available in following thickness:

- 6 mm (0.24 inch)

- 9 mm (0.35 inch)

- 12 mm (0.47 inch)

- 18 mm (0.70 inch)

Advantages and Disadvantages of PVC Board:

Advantages:

- These boards are made light weighted materials, can be transported easily. Therefore handling and transportation of PVC board costs lesser.

- The maintenance of this material is low also no need to apply inner Laminates as well, as it is very smooth. You can apply any colour laminate on the outer part according to your choice and preference.

- Good quality PVC board can have good water resistant properties and can be termite and borer free.

- They can be easily recycled and do not bring any kind of burden on the environment.

- PVC boards are self-extinguishing and cannot catch flame. It has a UL-94 flame rating, which is the highest rating in terms of fire resistance.and sound insulation is very good in case of these boards.

Disadvantages:

- They can easily sag if not installed properly.

- These boards are prone to scratches that can not be covered up.

- Sometimes pests and insects may occupy the hollow spaces, which can cause unhygienic conditions.

- It is advisable to use hardware and hinges compatible with plastic to minimize deformities

Application of PVC Board:

PVC board is compatible for interior as well as exterior work

Interiors:

It can be used for various purposes such as bathroom and kitchen cabinets, furniture, partitions and walls,doors and window frames etc.

Exteriors:

The exterior use is quite similar to WPC board such as exterior furniture, swimming pool deck, fencing and exterior wall cladding etc.

Picture Credits: Polytech

3. MDF Board: (Medium Density Fiber Board)

It is an engineered wood which is obtained from breaking down hardwood and softwood particles fibers. These fibers are joined together by using wax to produce the final result by applying pressure or high temperature. Since it is made up of small wood fibers, there are no visible wood grains or knots.

Picture Credits: Vinawood

MDF Board is available in following sizes and thickness:

- 2400 mm x 1200 mm (3 mm, 4.75 mm, 6 mm, 9 mm, 12 mm, 16 mm, 18 mm, 25 mm, 32 mm)

- 2400 mm x 1800 mm (16 mm)

- 2700 mm x 900 mm (18 mm)

- 2700 mm x 1200 mm (12 mm, 18 mm)

- 3600 mm x 1200 mm (3 mm, 4.75 mm, 6 mm, 9 mm, 12 mm, 16 mm, 18 mm, 25 mm, 32 mm)

- 3600 mm x 1800 mm (9 mm, 12 mm, 16 mm, 18 mm, 25 mm, 32 mm)

Advantages and Disadvantages of MDF Board:

Advantages:

- It is cheaper than the WPC and PVC boards.

- The surface of MDF board is smooth and it get easy to paint it for finishing result.

- It has dense fiber which make it suitable for designing interiors.

- MDF board is easy to handle because it can be easily cut and carved as per the required design.

Disadvantages:

- MDF board soak water and other liquids very quickly and get swells up if not treated properly.

- It can sag easily as the material is quite heavy due to dense fibers.

- Sometimes there is difficulty to hold nailing and screwing because of it heavy weight.

- Additional finishing material or laminate is required for final output as per the required design.

Application of MDF Board:

It can be used in making furniture, cabinets and shelves, Flooring, decorative interiors, doors and windows frames.

Generally MDF board is suitable for interiors works only and not much recommended for exterior purpose. This is due to the drawback that MDF board is not water proof materials and soak moisture instantly if not treated properly. So, it is advisable to use it only for interior designing purpose and if used for exterior then first make it water proof using it materials like laminate, veneer or paint etc.

Picture Credits: TESA

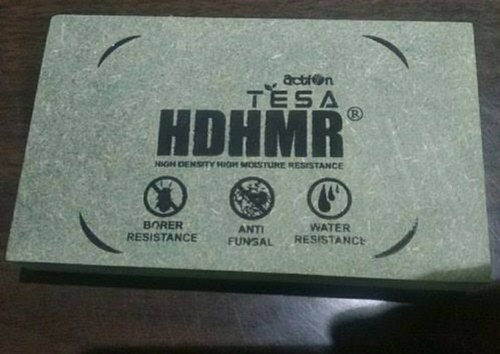

4. HDHMR Board: (High Density High Moisture Resistant Board)

HDHMR Board is made up of the combination of fiber chips and wood waste by mixing them together in a homogeneous mixture.These are pressed together in a single layer to form a robust high density board. High density is achieved through hard wood particle board with special glue pressing technique. These boards are mainly used at the places which are mostly exposed to high moisture content.

HDHMR Board is available in following sizes:

- 1220 mm X 2440 mm ( 3 mm, 5.5 mm, 8 mm, 12 mm, 16 mm, 18 mm

- 2155 mm X 795 mm ( 3 mm)

Advantages:

- First thing that these boards are highly water resistant and it is achieved through special glue pressing technique that makes it more water resistant than any other boards like PVC or WPC.

- HDHMR Boards are quite low maintenance. Users need not to spend much time maintaining them, they can be easily cleaned using the damp cloth dipped in lukewarm water. These boards can not be scratched easily if used with care.

- Termites can create unhygienic conditions inside the living or kitchen spaces. Termites are always in search of cellulose present in the wood. But in case of HDHMR board, during the process of making fibres the wood chips are steam cooked resulting in removal of all food content thereby making it Termite/Borer resistant, as these insects attack the wood in search of food only.

- It has multi-dimensional bond combined with single layer of special glue which do not allow to loose it strength easily. Therefore HDHMR board has got high screw strength, almost close to 10 times more than the usual block boar or ply.

- Talking about the cost, these boards are quite cost effective. Compared to others they are available in half of the cost.

- These boards are made up fiber chips and come with pre-paint/polish surface. This feature help in creating glossy finish using veneer pasting which do not require any further finishing.

Disadvantages:

Despite of so many advantages HDHMR Board has few disadvantages too which are listed below:

- These boards are heavy in comparison to others which sometimes can be difficult to handle the material in many ways like cutting and shaping.

- After long-term use, some HDHMR boards might bend and lose shape. This can also happen if you store HDHMR boards under poor conditions for a long time.

HDHMR board is no doubt a good choice for the interior and exterior works but after long-term use, some HDHMR boards might bend and lose shape.

Application of HDHMR Board:

There are numerous applications of HDHMR board and few of these are: Kitchen Shutters, Furniture where risk of moisture exist, Door Shutters, Packing Industry, Shoe Heel, Partitions, Outdoor Fixtures like election cutouts or similar applications

Picture Credits: Commercial Design

5. Plywood board:

Plywood board is an engineered wooden material made out of different layers of veneer. Veneer refers to the thin slices of wood usually thinner than 3mm thickness which are glued together to form plywood board. The more the number of layers the stronger the board will be. Wooden veneers provide great strength and flexibility to the board.

Plywood board is available in following sizes and thickness:

- 1220 mm X 2440 mm (3 mm, 4 mm, 6 mm, 9 mm, 12 mm, 15 mm, 16mm, 19 mm, 22 mm and 25 mm)

Advantages:

- Plywood has good strength and durability as compared to MDF board.

- As mentioned above the board is available in different thickness ranges from 3 mm to 25 mm.

- It can provide smooth finish with the use of polish, paint or any type of colorful laminates.

- Plywood board is easy to screw and also it can hold it well.

- One of the most versatile materials because it has endless use for indoors as well as outdoors, different densities and sizes of plywood can be used for various purposes and a great material for doing intricate wooden work.

Disadvantages:

- Plywood need a final finishing either with laminate or veneer.

- It is difficult to cut and mold the plywood.

- Also these sheets are little expensive as compared to other wood based sheets.

Application of Plywood:

These can be used for various purposes for indoors and outdoors. For indoors these can be used for making floors, wardrobes, cabinets, doors, shutter and walls. Also for headboards and foot boards, wall paneling and structure for indoor and outdoor furniture.

Picture Credits: Hanuman

So, these were the 5 major materials used for interior and exterior building designs of any building. Above discussed materials are not only materials available in the market and there are numerous others also. You can choose the materials as per your requirement and need. I hope you have liked this blog on 5 major materials used for interior and exterior building designs.

If you liked this blog, please let me know through your comments. Please share it with other people who are passionate about architecture and design. Contact us in case of any queries and also read my previous blogs related to architecture and travel. Thank you.

Today a reader,tomorrow a leader!

I am always invstigating online for articles that can assist me. Thx!

Thanks